AGH - UNIVERSITY OF SCIENCE AND TECHNOLOGY

Faculty of foundry engineering

DEPARTMENT OF ENGINEERING OF CAST ALLOYS AND COMPOSITES

St. Reymonta 23, 30-059 Kraków

CHARACTERISTICS AND SCOPE OF ACTIVITIES OF THE LABORATORIES

Following laboratories are included into the department:

Cast Iron Laboratory

Cast Steel Laboratory

Laboratory of the Metal Engineering, Metal Examination and their Heat Treatment

Laboratory of the Crystallization of Alloys and Composites

Laboratory of the Computer Modelling of the Crystallization Processes

Laboratory of the Engineering of Casting Surface

Laboratory of non-ferrous Engineering Alloys

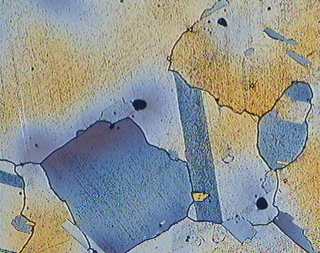

Cast Iron Laboratory

|

Full Prof. Ph. D. of Science Edward Guzik |

|

EQUIPMENT OF THE LABORATORY:

Electrical induction furnaces, capacity 10 up to 25 kg, furnaces for heat treatment, optical microscopes, scanning microscope, apparatus for thermal analysis; the special furnaces, i.e. cupolas, in two iron foundries cooperating with the department can be utilized on-line, for carry out exercises with students.

SCOPE OF THE ACTIVITIES:

Theory and praxis of processes occurring in the cast iron melting processes.

Improving of cast iron through its treatment in liquid state outside the furnaces.

Technology of producing the high-grade cast iron (inoculated cast iron, cast iron with the vermicular and nodular graphite, ausferritic cast iron, alloyed cast iron, malleable cast iron).

Processes of forming the structure and properties of cast iron.

Examination of the surfacial layers of iron castings.

Technology of production iron castings with wall thickness from 1 milimeter to some hundreds millimeters.

Examination of the foundry and utilization (herein mechanical) properties of cast iron.

Cast Steel Laboratory

|

Ass. Prof. Ph. D. of Science Barbara Kalandyk, univ. lecturer |

|

EQUIPMENT OF THE LABORATORY:

Thermobalance for examination the resistance of the alloys to high temperature, Miller apparatus for examination the wear resistance, LECO apparatus complex for determination the oxygen, nitrogen and hydrogen contents, Neophot 32 microscope with a camera and programme for image analysis, furnaces for heat treatment of metals, a stand for determination the oxygen activity in liquid steel.

SCOPE OF THE ACTIVITIES:

Optimization of the technology of melting steel for castings.

Treatment of liquid steel outside the melting furnaces.

Melting of the low-carbon grades of the ausferritic steel for castings.

Crystallization of steel castings.

Strengthening of steel castings with the help of microadditives.

Examinations of the resistance of steel castings to the high temperature (up to 1000°C) in the air atmosphere.

Examination of wear resistance of the steel castings.

LABORATORY OF THE METAL ENGINEERING, METAL EXAMINATION AND THEIR HEAT TREATMENT

|

Ph. D. of Science Edward Tyrała, univ. lecturer |

|

EQUIPMENT OF THE LABORATORY

Metallographic grinder Metasinex, polisher Montasupal PM-2 and Met-3 (small) as well as great (Reichert and Neophot 1), metallographic microscopes and microscope Leica MEF4M with the camera DC100, laboratory resistance furnaces KO-14 and PM-2 as well as great resistance furnaces POK, PIT resistance furnace PEW-18, salt-furnace PES-01, quenching tanks, resistance testing machines ZDM-30 and ZDM-10, hammer testing machines type Charpy, hardness testing machines (Brinell, Vickers, Rockwell and Shore), machine for testing wear resistance type MAN, machine for testing fatigue resistance RM-50, Dilatometer: optical DI-105 and mechanical for testing in a protective atmosphere by the temperature up to 1050oC, ultrasonic defectometer types 510 and DUR-20-II, ultrasonic thickness gauge, magnetic defectoscope, complex of apparatus for fluorescent examinations.

SCOPE OF THE ACTIVITIES

Examinations of structures, properties and defects of castings and cast composites.

Optimization of the parameter of the heat treatment of foundry alloys.

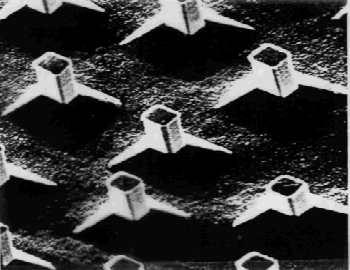

LABORATORY OF THE CRYSTALLIZATION OF ALLOYS AND COMPOSITES

|

Ph. D. of Science Ewa Olejnik, univ. lecturer |

|

EQUIPMENT OF THE LABORATORY

Equipment for monocrystallization and directed crystallization of the alloys and cast composites; Rentgen diffractometer, induction vacuum furnace capacity 1 kg, equipment for crystallization by increased pressure, equipment for visualization of the crystallization processes

SCOPE OF THE ACTIVITIES

Examination of processes of the crystallization of alloys and its visualization.

Production and examination of the materials of advanced technology, especially of the composites, intermetallic and cast metallic glasses.

LABORATORY OF THE COMPUTER MODELLING OF THE CRYSTALLIZATION PROCESSES

|

Full Prof. Ph.D. of Science Andriy Burbelko |

|

EQUIPMENT OF THE LABORATORY

Professional systems of the computer modelling of the crystallization and flow processes type PROCAST, CALCOSOFT and FLUENT as well as of calculation of the diagrammes of the phase equilibrium in the 3D space, type THERMOCALC.

SCOPE OF THE ACTIVITIES

Computer technology in the foundry processes.

Statistics and computer treatment of data.

Computer utilizing programmes; computer graphics and computer aiding to the technology.

Computer methods of examination of the phase transformations in the range of the cooling and crystallization of castings.

computer methods of optimization of the cooling and feeding of castings.

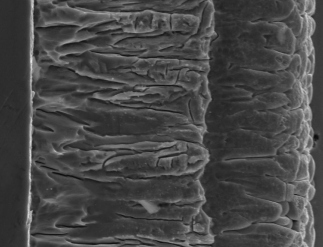

Laboratory of Casting Surface Engineering

|

Full Prof. Ph. D. of Science Dariusz Kopyciński |  |

EQUIPMENT OF THE LABORATORY

Stand for spreading of the protective zinc layers over the iron and steel castings; furnace for annealing the samples prepared for galvanizing.

SCOPE OF THE ACTIVITIES

Examination of partial layers in the zinc coatings.

Modelling of the crystallization of zinc coating.

examination of the properties and the corrosion resistance of zinc coatings.

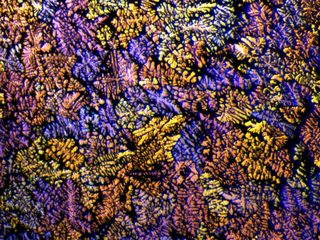

LABORATORY OF NON-FERROUS ENGINEERING ALLOYS

|

Full Prof. Ph. D. of Science Marcin Górny |  |

LABORATORY EQUIPMENT

Heat treatment furnaces, LEICA optical microscope with automatic image analyser Leica QWin, scanning electron microscope JEOL, devices for cutting and specimen preparation for metallographic observations, equipment for thermal analysis.

FIELD OF ACTIVITY

Crystallization of aluminium alloys, copper alloys, superalloys, composites "in situ".

Production technology of non-ferrous alloys.

Optimization of metallurgical treatments.

Processes shaping the structure and properties of non-ferrous alloys.

Metallurgy and heat treatment of non-ferrous alloys.

Made by: Sebastian Sobula

Updated: 04.2021